S54B32 - M3 E46 Engine Second Life: Rebuild

Check Engine on the Dash

Upon the MAF sensor replacement the car felt much better but it was running rough and was often stalling at idle while coming to a standstill. The new MAF live data was indicating 18 kg/h air flow at idle with no load while the old one was giving 26 kg/h. As there was no reference data available we started asking people with know-how here and there about what should be considered real values of a healthy MAF. After we tested a fine working MAF sensor from another car and got some feedback on the matter from popular internet forums all indications were that the value of the new sensor is correct. The faulty MAF was making the engine to run way too rich on fuel which made sense why there was so strong gas odor from the exhaust. Upon ECU adaptations reset the idle went back to normal, smooth and stable. By coincidence or not on the very same day the “Check engine” light came on steady and the engine began to run very unusual – weak in the low rpm range, noisy and vibrating, the fuel consumption went up in the sky…

The engine complained with fault code related to lack of synchronization between the crank shaft and the inlet cam shaft. Sometimes there were even issues with the engine start – it was cranking but no ignition. All symptoms were pointing to a faulty crank shaft position sensor. Considering the VANOS was fully rebuilt, spark plugs and ignition coils were good, the MAF was new, the subject two cam shaft position sensors and the front lambda probes were the only items that could affect the engine performance and have never been replaced. There were ordered only OEM parts and besides their replacement I requested compression ratio to be measured on all cylinders. This was really the last thing that eventually can make the engine so under-powered. Even though there was already a very important conclusion made – monitor your MAF live data! As the mileage is building up it would start increasing the value of the measured air flow which will lead to wrong mixture enrichment. Should it exceeds 20 kg/h or mileage goes beyond 100 000 km replace it along with the front lambda probes. S54 uses narrow band probes and after the quoted mileage they become really inert.

Trial and Error

The subject sensors were replaced, the engine was no longer throwing any fault codes. It was running smooth and that nasty gas odor behind the car was gone completely. But… as people say too much good is not good! The compression measurement indicated scary low values on cylinders 2 to 5. The lowest was measured on cylinder 2 – just about 6.5, while on 6 it was at the nominal of 11.5. That was clear proof about the actual sentence – the head gasket was dead. This is another dangerous and very common problem on S54 engine (especially in Europe, probably due to the fuel standards). This problem might have no visible symptoms except reduced power output but could lead to a catastrophic consequences for the iron block. The wall between the cylinders is quiet thin – just about 2-3 mm. That’s where the significant thermal stress accumulates which leads to cracks propagation in the metal head gasket. Then over time it completely burns which then leads to loss of pressure between adjacent cylinders. Except for wrong burn process in the cylinders that leads to thermal corrosion mainly on the block.

The face of the block has allowable limit for machining but if it is exceeded then the block is history. It is considered that the new head gasket will not be able to seal the interface between the block and the head with the presence of corrosion spots in any of the contacting surface. So I had to take an immediate decision. To keep driving the car like this was like playing a Russian roulette. The repair was estimated to reach high 4-digit number. Considering that I had no plans of selling my E46 I decided to ground it and carry on a full rebuild of the engine…

On the Surgical Table

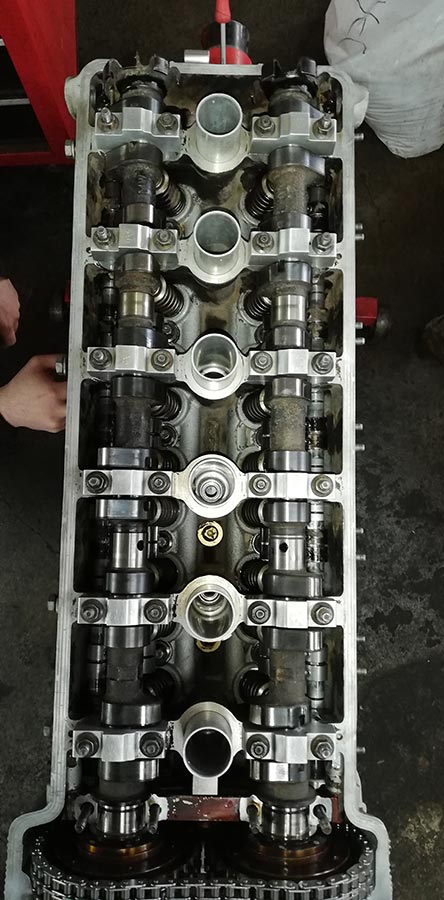

As early as day two since the work started after removal of the front axle the engine was removed downwards from the engine bay and disassembled at stage head off the block. As expected the head gasket was completely cracked alongside the middle part where the engine block is thinnest. The good news though was there was no visible damage to the block’s face. However it is mandatory the block to be machined prior fitment of the new gasket in order to meet sealing requirements. It was also decided to replace the main and the rod bearings of the crank shaft, the pistons sealing rings, the timing chain and everything else that would be considered defective. The second good news was that except for 6 valve rocker arms and one oil pump chain guide everything else was in pretty good shape.

Considering that the engine had run for almost 300 000 km and that was it’s first rebuild that was more than a good news! It was important to inspect the condition of the rod bearings since this was something we did preventively exactly 80 000 km from now. They show absolutely reasonable level of wear which gave me another solid optimism! And also a real proof that frequent oil changes and daily driving of the car will not allow something bad to start developing inside the engine.

Significant part of the work involved cleaning of everything from sticky oil residuals and coking – this was absolutely the right time to do it. The head was also sent for machining of it’s face and valves fitment check. The rest was more or less routine work and step by step the engine was re-assembled with new bearings, piston sealing rings, timing chain and all kinds of gaskets and seals. A break-in was required for the new piston sealing rings which meant smooth engine warm up and moderate revving up to 3000-4000 rpm.

The Final Result

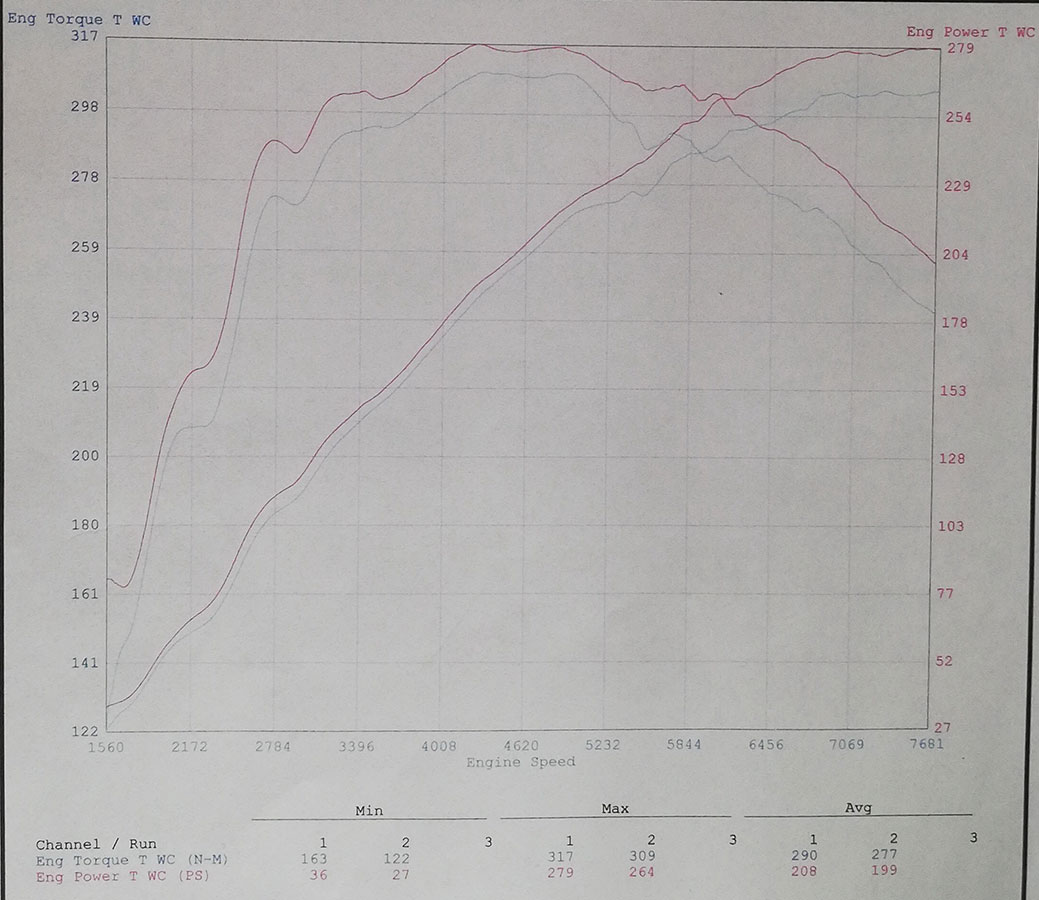

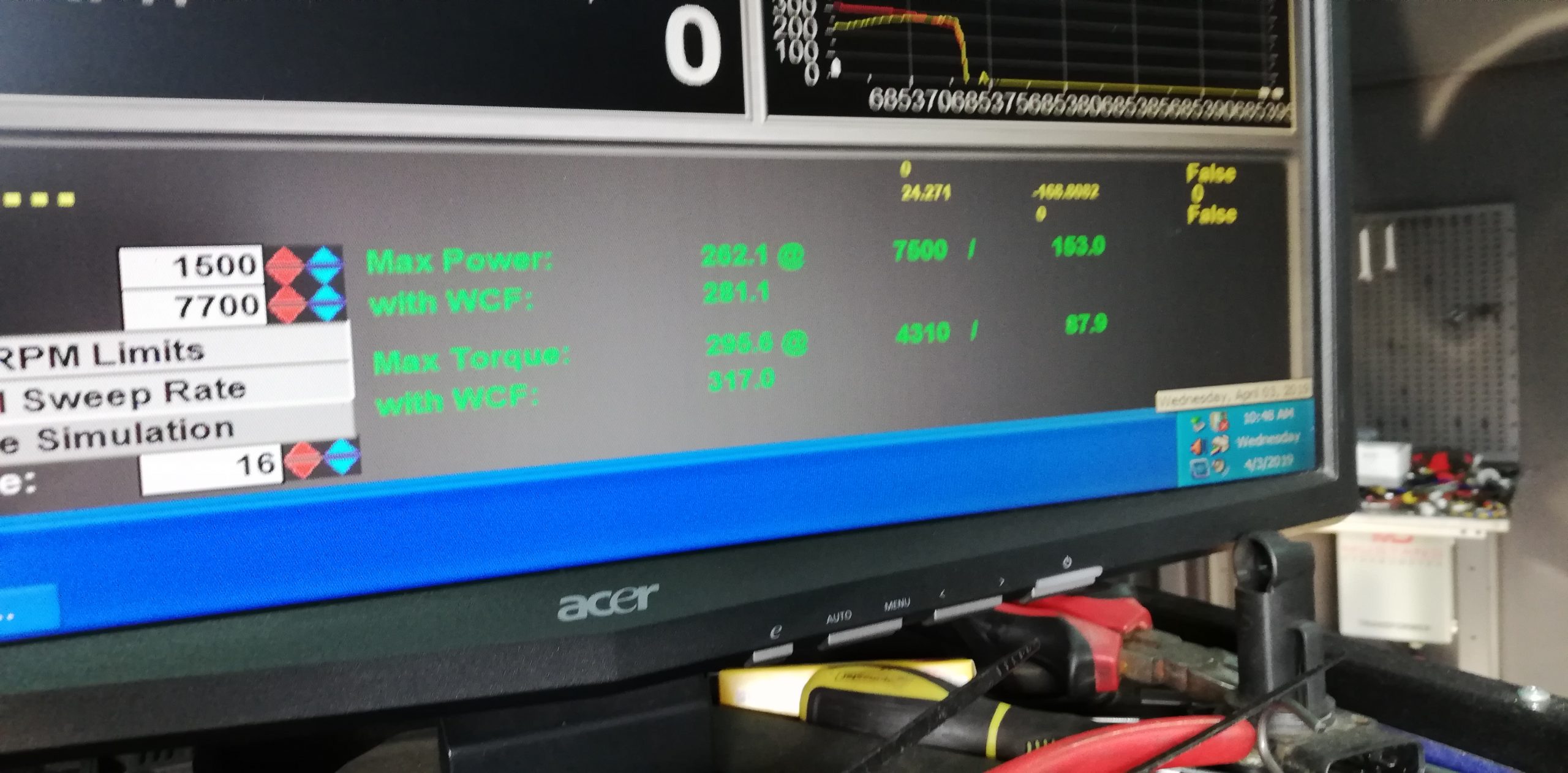

Even with the first engine start as I took my car back from the shop it felt like a new heart was beating in my M3. The engine fired up literally from 1/8 turn on the crank, runs really smooth, the fuel consumption even went down. After the required break-in of about 2 000 km the time came to complete what remained unfinished at the remap last fall. Just after 3-4 mappings the car pulled 280 whp 320 Nm (Mustang dyno) at 35 ‘C in the intake. Good 60 whp on top of what was measured prior the rebuild! My S54 went indeed through a massive rebuild but the way the car runs ever since then is giving me confidence that it’s heart has just begun a second life. And it would keep on going like that for the next 250 000 km… 🙂